Experiment 10 - SHION: Smart Thermoplastic Injection

Experiment description

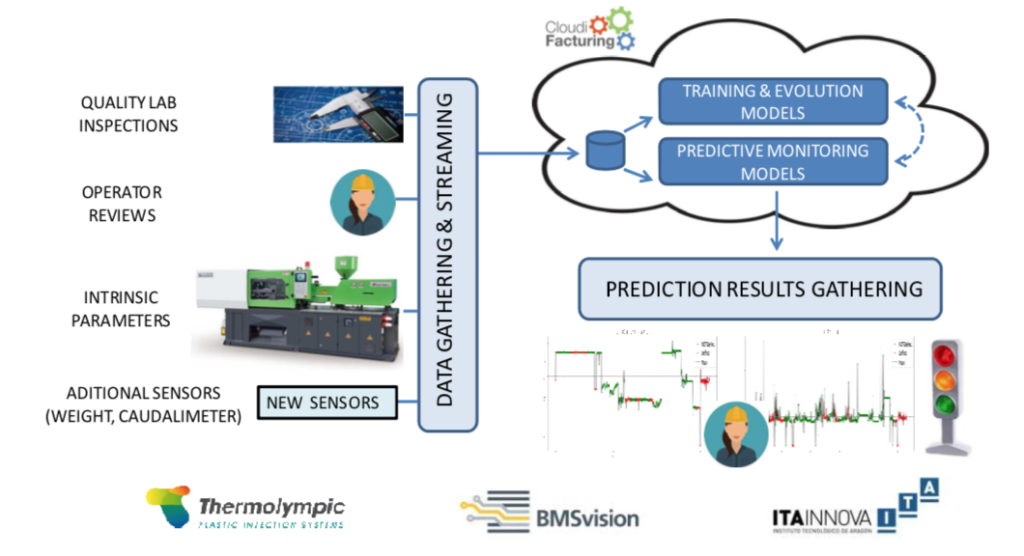

The proposed approach into use cognitive technologies (specially Deep Learning algorithms) will help to be able to extract the knowledge to generate a predictive model to detect when a defect in the production is going to happen. Therefore, mainly information of the Thermoplastic Injection process itself, with the intrinsic parameters of the injection machine for each piece will be considered, as well as context information like environmental conditions, operators review, quality laboratory inspections and piece weight. Constant evolution of the cognitive models generated is also supported.

Technical Impact

For this experiment, two Thermolympic production lines are considered for the use case. This approach will enable:

- Preventive detection of anomalies and reducing internal and external non-comfomities

- Predictive maintenance for tools and machines

- Operation parameters optimisation by assisted lesson learned

The shop-floor workers (production/quality) will be advised of undesirable states (deviation on machine parameters, fail presence). It will reduce the required parts manual inspections and set-up cost while keeping or improving quality rate.

Real time integration of production data (ERP, machine, parts, environment) for feeding back workers using evolutionary AI models.

Economic impact

The first year, data analytics system linked to current machine running in two selected machines will become a new service. Turnover will be an estimated of 50,000€. Two new positions will be required. Develop sensors, scales and hardware sellers are among the ones which will be counted like new contacts.

Experiment Outcome

SHION improves the added value of the prospective end-user companies both in productivity and quality areas, opening the possibility to reach new OEMs and Tier 1 industrial customer where the quality requirements need to achieve higher levels of excellence.

It is expected to consolidate the current customers, increasing the business link through new projects while at the same time, objectives reached will create added value to the products in the company opening windows for new potential customers in current and new markets in thermoplastics sector. In the long term, with a full setup of the solution, the cost of the part should be reduced through improvement of the injection processes and a reduction of the quality costs (customer claims and scraps generated).

“CloudiFacturing is the natural outcome for any company that want to be at the vanguard on Industry 4.0. With SHION, we accomplish a new step in our long term objective for a company fully connected, efficient and competitive, were the workers have available all the relevant information in real time for continuous improvement.”

Jorge Millán Santacruz - Thermolympic S.L. Operations Manager

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).