Experiment 9 - CAPSUle: Cloudification of image analysis for human measure collection for personalised safety protection clothing engineering and production

Experiment description

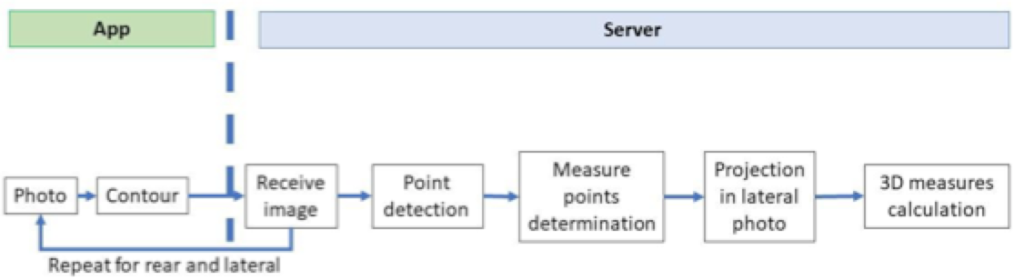

The experiment aims at exploiting HPC access granted by CloudiFacturing to enhance machine learning simulation process, core of human measure collection by mobile image analysis, provided by I-Deal (IT). The measures will be uploaded into clothing CAD system of the industrial end user TroTusTex (RU) to produce safety protection apparel.

The process must fulfill UNI EN ISO 13688 apparel measure precision to grant safety protection requirements and must be anonymised to protect the identity.

Technical description

Currently the measures of the workers and the matching between them and the clothing size is carried out by hand. The workers are required to self collect their measures: the error percentage reaches 83% of the total in comparison with a professional tailor.

At the moment, the level of errors caused by manual collection cause up to 50% production not respecting the required tolerance of measures, causing costs for repair and, in the worse cases, for repeated manufacturing.

The successful implementation of the experiment will impact on worker comfort, precision of production, reduction of wasted resources due to imprecise human anthropometric data collection, with positive environmental and economic benefit.

Economic impact

Protective clothing segment , where TroTusTex competes, is worth USD 7.33 Billions in 2016 and is expected to reach USD 9.95 Billions by 2021.

On i-Deal side, the experiment is expected to enhance the success rate of the measure collection process of 70% by increasing the capacity of the application to extract precise measures in not controlled conditions.

User experience is expected to reach a >50% conversion rate at first measure collection attempt. The self learning algorithm training is expected to reduce of 95% the timing of update by the access to Cloud/HPC resources.

Experiment outcome

Accessing CFG HPC resources enabled TroTrusTex to overcome bottlenecks limiting the precision of the measurements. This will reduce the direct costs related with the definition of the worker’s size and/or measure collection for made-to-measure production. The solution is also expected to reduce the returns related with imprecise size or measure definition. The mew process will also reduce the manual input of human measures, which will be collected by the SizeYou app and directly sent to the CAD tool for manufacturing. The new CFG-based solution will provide a new service to companies that need technical protection clothing by providing a mobile self-collection instrument to workers instead of the current manual size assignment.

This solution will open the market of worker protection clothing and, in the future, it can also be extended to sportswear. In addition, it will open the sector of product as a service, where protection clothing is lent to public sector organisations and companies instead of being sold. Finally, the huge amount of anthropometric data collected will be exploited, in aggregated form, to provide anthropometric analysis and simulation for all the sectors involved in the design of goods which must fit for human body measures.

“CFG technology provides i-Deal with the possibility to train new models to generate anthropometric measures in real time, to satisfy the specific needs of its customers. The service of the company and its capacity to support the needs of the market have been significantly enforced.”

Alessandro Canepa, Founder of i-Deal SRL

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).