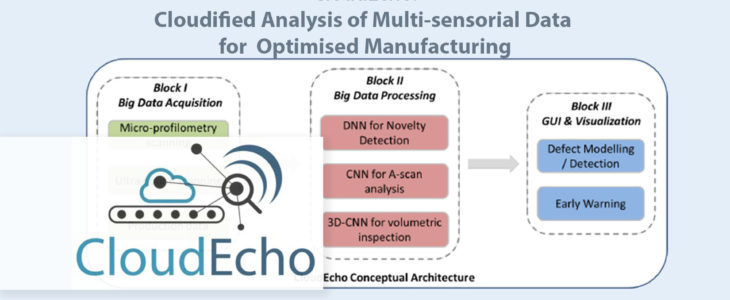

CLOUDIFIED ANALYSIS OF MULTI-SENSORIAL DATA FOR OPTIMISED MANUFACTURING

CloudEcho solution provides the capability to optimize and automate quality control by implementing deep multi-sensorial analysis using Deep Neural Networks for defect prediction and quality inspection in Hard Metal industry.

The experiment has also shown the potential of closing the loop between defect inspection sensors and machine sensors. Due to the partners’ knowledge, the implemented ultrasound scans were the first which are applied for defect inspection in hard metal industry. The microprofilometer model achieved general accuracy of 77.78%. The ultrasound model achieved general accuracy of 83.33% while the fusion model scored an accuracy of 88.24%. Considering these experimental results, the benefit of the fused model is evident and appreciable.

In addition, using CloudEcho instrumentation, we also studied the physical properties of hard metal parts and produced 3D point clouds. Using this combined knowledge realistic digital twins of hard metal parts can be produced and later used during the design phase.

Check out their new video, featuring their completed solution.

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).

The project CloudiFacturing receives funding from the European Union’s Horizon2020 research and innovation programme (Grant No. 768892).